Magnets for Metal Fragment Control

By Debby Newslow, President, D. L. Newslow & Associates, Inc.

In association with Kevin Baker, Active Magnetics Research P/L (AMR)

Introduction:

When considering existing and potential foreign material hazards, metal fragments are consistently identified as a concern. Depending on the situation, the potential risk (how significant the outcome) and significance (how likely it is to occur) often results in the identification of a significant hazard that must be controlled through a CCP or at a minimum, through a prerequisite program which includes the use of a metal detector and/or magnet strategically placed in the process. When discussing food safety, foreign material related incidences are actually the most frequent hazards identified. Since these incidents usually affect a limited few, foreign material hazards do not receive the publicity that a pathogenic, bacterial contamination receives which has the potential to harm large numbers of consumers with each incident.

The objective must be to produce a product that is free of any metal fragment contamination. This can be accomplished through the reduction of contamination, risks, and consequences such as: controlling the hazard by eliminating or reducing it to an acceptable level using effective prerequisite programs (PRPs) or by control applied at an identified Critical Control Point; and verification that the PRP or CCP is monitored and confirmed effective through a well-defined food safety, GMP, and Food Safety Management System Internal Audit program.

This article provides a basic foundation for achieving success by controlling metal as a foreign material hazard. Control of metal begins with the control of raw materials by effectively communicating with suppliers through a well-defined, implemented, and on-going supplier management program along with a defined program for magnet testing of ingredients and incoming raw material supplies. This type of program includes metal detectors and magnets designed for specific functions and locations, strategically placed in the process. It also addresses the verification and validation of the equipment by a qualified external company and also verification performed and managed through an effective internal preventive maintenance program.

Let’s first discuss the role of magnets in the process. It is critical that a magnet program be implemented and maintained in a manner that is effective to the process overall. It is recommended that the strength of the final magnet measure at 10,000 Gauss. Magnet strength must be monitored at a predefined frequency sufficient enough to provide confidence in the program. In addition, magnets must be cleaned and inspected for damage on a defined schedule. Findings must be evaluated to determine the source, and the source either corrected or eliminated.

It is recommended that the strength of the magnet be verified at least annually by a third party using a calibrated Gauss Meter, with records confirming traceability to an NIST or known standard to confirm its accuracy. Depending on the process and information received through verification, the actual performance of the magnet for its application can also be validated. It is also recommended that depending on the process and product, that verification using a calibrated Gauss Meter be performed internally as part of the preventive maintenance program either quarterly or semi-annually.

Depending on the nature of the product, the process must also be equipped with a well-designed metal detector and/or X-ray machine that is also strategically placed in the process to evaluate the final products. It is critical that this equipment is also verified for effectiveness and accuracy by a third party calibration service company on a predetermined frequency (minimum annually) based on the products and process. At a minimum, a prerequisite program requiring trained operators to monitor and record at a defined frequency (i.e., every 30 minutes) using control pieces appropriate for the specific process must also be defined, implemented, and maintained to confirm effectiveness of the metal detector.

This article provides more detail on the actual requirements for monitoring the effectiveness of process magnets, comparing the well-known Pull Test and Gauss Meter measurements. The complementary effect of a synergistic and strategically placed magnet and metal detector in a process to monitor, control, and/or eliminate metal as a foreign material hazard is also reviewed.

The most common locations for the placement of magnets are

- Product Intakes;

- Ingredient Intakes;

- Equipment Protection - High Impact;

- Indicator Magnets;

- Final Finished Product/Packing magnets;

- Lab Magnets for testing finished products and ingredients.

Potential risks and consequences of inferior magnets which do not meet today’s standards include:

- Product Contamination;

- Consumer Injury;

- Product Recall;

- Brand Name Risk;

- Equipment Damage/Failure - High Impact;

- Product Contamination;

- Loss of Product;

- Down Time;

- Costly Repairs;

- Ongoing Maintenance.

Additional risks related to inferior or ineffective Metal Detector programs include:

- Malfunctioning;

- De-Sensitization;

- Product Wastage;

- Nuisance Trips;

- Down Time.

Let’s discuss Magnet Verification:

Magnets and magnetic separators are used in the food industry worldwide to extract metal contamination from food product streams, reducing contamination risks and consequences and to satisfy PRP/CCP control and food safety audits. Magnets are often installed in the final and critical product locations as a safeguard against metal fragment contamination. Essential criteria for effective results include:

- Strength of the magnet at a minimum of 10,000 Gauss;

- Pole spacing at a maximum gap of 22mm in 1” diameter bar and grate magnets;

- Objective evidence (records) available confirming magnets are validated and verified to an NIST or known standard at time of installation and then a minimum of annually thereafter;

- Minimum coverage at approximately 80% of the product stream;

- Sizing at maximum product contact without product blockage or hang-up;

- Cleaned at a defined frequency either manually or automatically;

- An efficiently designed retention area on the magnet to retain collections of magnetic contamination between magnet cleanings.

It is necessary to develop, implement, and maintain an effective magnet verification program because magnets CAN lose strength over time and very rapidly in some circumstances of use. Even if a magnet appears to be extracting metal, the following questions must be asked:

- “What is getting past the magnet?”

- “Is the magnet sufficiently strong enough for the application in which it is placed?”

- “What is the most effective means to determine the strength of the magnet and ensure that its function within the process is effective?”

Let’s review the two main methods used to test the strength of magnets: the Pull Test and the Gauss Meter Test.

The Pull Test Method:

Pre-1960, the Pull Test Method was pioneered in an attempt to determine the relative strength of magnetic equipment. The "pull test kit" consists of a hand held scale device and a variety of test pieces. The test piece used depends on the type of magnet being tested. Although the Pull Test Method has been used for many years, the pioneers of the method stated, “'We suggest you use the kit not to verify the values". The "Pull Test" method is now seen by some major auditing and standards bodies as ‘outdated for magnet verification’.

Is the "Pull Test"- method accurate? Pull test values can and will vary. It is not uncommon for different individuals to record different results. An experienced person performing this test on a regular basis may obtain meaningful comparisons of magnet strength over time; but again, results many times do vary even with the same individual doing the test.

The “Pull Test” method was designed to put an approximate value on the holding force of a magnet or the pulling force (field depth) of a magnet (i.e., a plate magnet). It may more appropriately be called a “hold” test, as it is mainly used to compare the surface hold of one magnet to another. It is also important that some modern day contaminants such as stainless steel fragments and magnetic stone may react weakly to a magnetic field. Such products ideally must “contact” the magnet surface which makes a pull test measuring force at a distance almost irrelevant.

The Gauss Test Method:

The Gauss Test Method of verifying magnet strength is used increasingly in the food industry because of its accuracy and ability to verify, validate, and accurately compare strength loss trends over time. This method uses a Gauss Meter reading being made on the surface of the magnet which provides a flux density measurement. The Gauss Meter Test Method of verifying magnet strength is used increasingly in the food industry because of its accuracy to verify and to accurately compare strength loss trends over time. New Gauss Meter technology is being rapidly adopted by major food companies because it does give a more definitive and specific measurement. The Gauss Meter must be calibrated to an NIST or other known standard with records (calibration certificate) maintained confirming its accuracy. The Gauss Meter is suitable for testing a wide range of magnet strengths between 1,000 and 13,000 Gauss. This test method is endorsed by the HACCP International1.

| PULL TEST | GAUSS METER TEST |

| Used in all industries pre-1960 to present times. | Used increasingly in food industry since 2010. |

| Empirical Comparative. |

Definitive, Accurate, Repeatable, Calibrated. |

| Originally used mainly on plate magnets up to 3,000 Gauss. | Plate magnets now used less in food industry. |

| The surface test for “hold” was mainly used on grate magnets below 5,000 Gauss. |

Surface strength of magnets is generally 10,000 Gauss now for product security in food industry |

| Safety issues can result from sudden release of a test piece from high strength magnets. | No safety issues with Gauss Meters |

| No practical standards in earlier times for method of testing magnets in the food industry other than the pull test method. |

Gauss Meter Test conforms to current standard for final Magnets in food industry1 |

| Rebound of release from magnets over 5,000 Gauss can cause inaccurate measurements. |

Modern calibrated Gauss Meters can measure all strengths accurately from 1,000 Gauss > 20,000 Gauss |

In today’s world, it is evident that the older “pull test” method approximations are declining in acceptability wherever product and brand name security is critical.

Why must magnets be verified and validated?

Four very good reasons include to:

- Initially confirm that new, final magnets are within specified strength when purchased;

- Verify that specified strength has been maintained;

- Confirm full exposure to the product stream or flow:

- Confirm magnet is effectively controlling the hazard or potential hazard of concern.

A magnet that does not cover the product stream can be useful as an “indicator” but is not a sufficient magnetic separation magnet for product security.

Magnet verifications are very important, especially at a CCP and at a final process location, to confirm that the magnet is within tolerance. A Magnet Verification & Validation Report should be provided initially by the magnet supplier and then conducted every 2 years on intakes and plant protection magnets. Magnet verifications must be conducted with a calibrated Gauss Meter using properly endorsed procedures and providing a record that includes the testing results and traceability that the instrument used to test the meter has a current NIST or known standard certificate. Validation activities must be performed per defined requirements. This activity must provide the data that the magnets are effectively controlling the hazards.

Understanding the terms “verification” vs. “validation”

We have used the terms “verification” and “validation” many times in this text. Before further discussion, it is important to revisit the definition of these two terms as defined in ISO 22000: 2005.

Verification: “Confirmation, through the provision of objective evidence, that specified requirements have been fulfilled”. In other words, the operation is doing what it says it is doing following defined requirements.

Validation: [as related to food safety] “obtaining evidence that the control measures managed by the HACCP plan (CCPs) and by the Operational PRPs (OPRPs) are capable of being effective.” In other words, data is available to confirm that what is being done is the “correct” activity to control the hazard.

Most Food Safety Management System Standards and even basic HACCP criteria audits depending on their defined role in the process do require verification and validation of magnets and metal detectors either when identified as a Critical Control Point or as a Prerequisite Program.

It is recommended that magnets be verified through the use of a calibrated Gauss meter instrument at a minimum of once every 12 months in accordance with the 0909MAGSEP1-20103 magnet standard. An effective magnet program includes with the annual calibration, magnet verification/validation report provided by a third party magnet specialized company that:

- Confirms individual magnets meet current standards;

- Confirms whether individual magnets are still as effective as when first installed;

- Provides the estimated coverage and magnetic strength for each magnet;

- Identifies potential risks of metal contamination;

- Provides specifications to address magnet needs;

- Suggests vendor options as to who can provide 0909MAGSEP1-2010 and meet the specification to maximize product protection.

Many food companies also test their magnet strengths “in house” between the annual audits. This is a good practice; if a critical magnet is exposed to demagnetizing factors or damaged, for example, it may never be within specification. Some companies run a test piece through a metal detector at regular intervals to make certain that the metal detector still conforms to requirements. Additionally, all magnets must be cleaned regularly to ensure that their efficiency is maintained. A magnet can be “shorted out” by many fine magnetics which lower its separation efficiency. It is recommended that “in house” calibrated Gauss Meter Kits be obtained for testing and monitoring the effectiveness of the magnets between the annual third party evaluation.

The following is recommended:

- Monitor magnet strength and maintain records of compliance;

- Ensure minimized pole band spacing related to the magnets' functions in your operation;

- Ensure and monitor (inspection and cleaning) product to magnet coverage;

- Maintain internal knowledge and access to pertinent reference information;

- Maintain familiarity with current international magnet standards such as 0909MAGSEP 1-20103 ;

- Review Codex Alimentarius design of experiments example for validation of magnets;

- GUIDELINES FOR THE VALIDATION OF FOOD SAFETY CONTROL MEASURES (CAC/GL 69 – 2008);

- http://www.codexalimentarius.org/input/download/standards/11022/cxg_069e.pdf.

Following are the seven "secrets" for effective metal fragment control:

- Magnet Strength: A minimum of 10,000 gauss

- Pole Spacing: Maximum gap of 22mm unless magnet bar diameter is 35 mm or greater

- Documentation: All magnets verified with a calibrated (confirmed accurate to a known standard) Gauss Meter at installation and then annually

- Magnet strength life and safety: High vacuum resinizing and use of high grade RE80TM magnet compound

- Coverage: Minimum coverage, approx. 80% of product stream

- Magnet Sizing: Maximum contact of product with the magnet without product blockage or hang-up

- Magnet Cleaning: Regular manual or automatic magnet cleaning

Below is an example of what can happen to an inferior magnet in the process:

The above picture is an example of a mechanical and magnetic failure of a low cost finger magnet.

This magnet initially measured 8-10,000 Gauss; however, in its damaged state, it is measuring 1,000 Gauss. What do you think of its current effectiveness?

The Role of the Metal Detector: Let’s discuss the magnet and the metal detector together as a team.

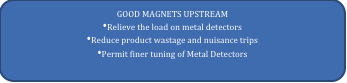

It is important to understand that an effective metal foreign material control program includes both a high grade magnet strategically placed in the process along with an efficient metal detector. Many respected organizations share the view that it is of ultimate importance that Ultra High Intensity Magnets be installed

upstream from high sensitivity Metal Detectors and/or X-ray units. An efficient metal detector is one that reliably indicates the presence of stainless steel or brass bolts, stainless steel nuts and washers, copper wire, and aluminum foil. Such a metal detector is invaluable to the process and more specifically the foreign material control program.

Stainless steel fragments and wires of 3mm size and under are usually work hardened. This means such fragments can be extracted magnetically along with other contaminants such as magnetic stone. The likelihood is great that without efficient magnets, much fine ferrous metal and fine magnetic fragments will pass through even the most sensitive metal detectors. Without efficient magnets, larger pieces will be detected by the Metal Detectors, but excessive product rejection may occur where the detector is properly calibrated. The causes of these rejections are often difficult to locate in bags or bins of bulk product. Consequently, it is much better to pull ferrous and other magnetics out through the use of effective magnets. Keep in mind that even the small fragments can result in product recalls. As stated previously, it has been generally accepted in many operations that metal detectors work much more efficiently in both wet and dry products when the metal detector is preceded by a magnet strategically placed upstream of the metal detector. It is common with such processes that with effective magnets, metal detectors become more efficient.

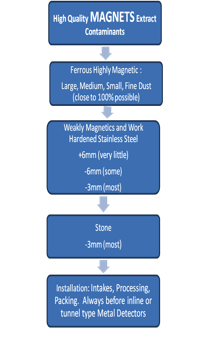

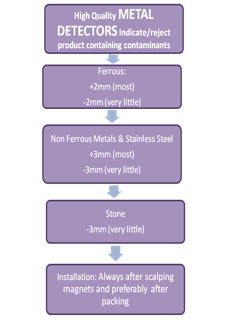

Combining MAGNETS and METAL DETECTORS for an effective program is outlined in the following chart. This chart provides a good focus of the limitations of both and how a magnet and a metal detector together compliment the functions of each, which will result in a sound foundation for an effective foreign material hazard program.

In conclusion, when evaluating the effectiveness of your magnets, look for

- Final product lines without magnetic protection;

- Under strength existing magnets;

- Inadequate magnetic coverage (less than 80%);

- Lack of feature to “retain” collections against product flow.

In our experience in today’s world of processing, magnets somehow have become either a forgotten piece of equipment or equipment that although placed in the lines, is just not monitored and maintained in the manner intended to remove fragments and protect the final products. It is not unusual to find magnets in a process that management doesn’t even know are there. Also, many time magnets are placed where they fit in the process, not necessarily where they would be best for the process. Others have magnets, but have no idea how often they are cleaned and what purpose they are actually serving in the process. At a minimum, an effective magnet program should meet the following guidelines:

- High Strength 10,000 gauss magnets for all final and critical magnets;

- 8,000 Gauss minimum may be accepted depending on location and function of the magnet;

- 10,000 gauss magnets for critical equipment protection;

- Maximum of 22mm pole centres for adequate coverage;

- Demagnetization features;

- Magnetic verifications by an independent external body performed at a minimum of every 12 months;

- Internal magnet verifications performed with a Gauss Meter;

- Pull Test is not recommended for consistent and meaningful information related to the strength and effectiveness of a process magnet;

- Maintain records to confirm compliance that magnets continue to meet current magnet specifications for performance and effectiveness.

For more information on magnet programs, verification, validation, the use of the Gauss Meter, or for a comprehensive evaluation of your magnets, please contact us at 407-290-2754.

References:

D. L. Newslow & Associates, Inc. (www.newslow.com) (US number: 407-290-2754)

Active Magnetics Research Pty Ltd www.amrconsulting.co

MAGNATTACK™ Global Magnetic Separation Equipment Manufacturers

www.magnattackglobal.com; USA TOLL FREE: 866 464 1492

- The International Magnet Standard (0909MAGSEP 1-2010 Food Safety Standard)

FINAL MAGNETIC SEPARATION DEVICES for REMOVING FERROMAGNETIC and WEAKLY

FERROMAGNETIC PARTICLES from FOOD PRODUCT STREAMS - A HACCP International Food Safety Standard (Available in US through www.newslow.com or through HACCP International on http://www.haccp.com.au/tools-downloads.php)